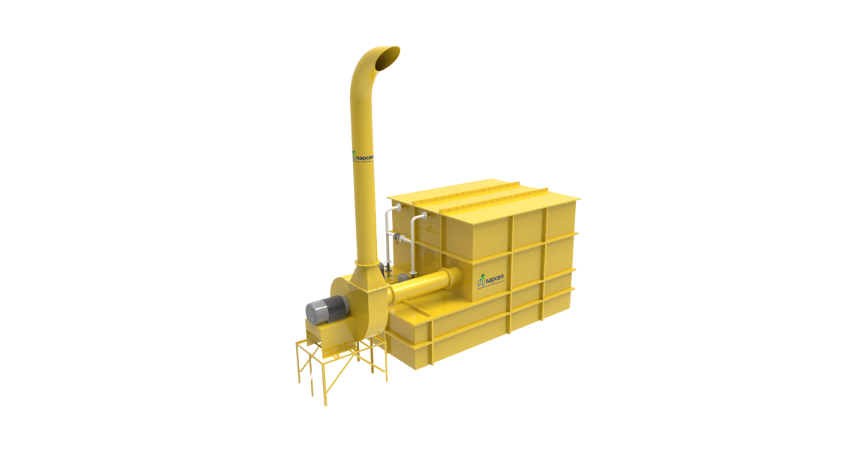

Here's how a chlorine scrubber typically works

-

Gas Inlet

The chlorine gas-laden air is directed into the scrubber from the emission source, such as a chemical plant or water treatment facility.

- Scrubbing Media

- Contact between Gas and Scrubbing Solution

- Neutralization

- Outlet