Tower Packing

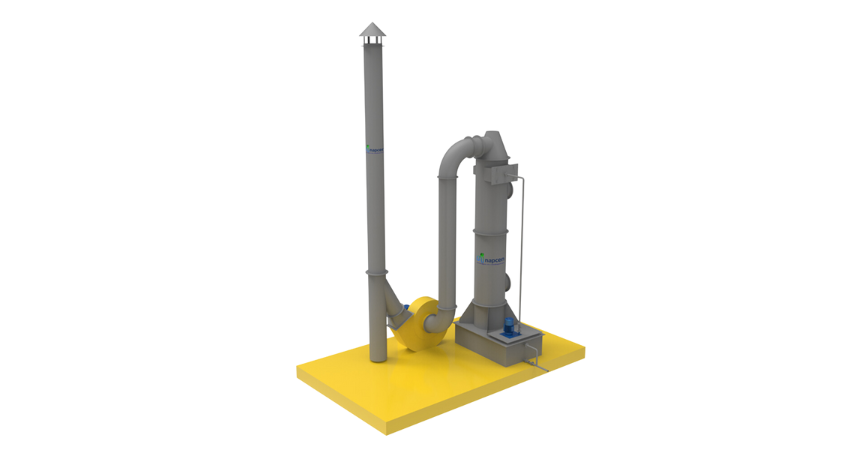

An Acid Fume Scrubber, also known as an acid gas scrubber or simply a fume scrubber, is a pollution control device used to remove acidic gases (such as sulfur dioxide, hydrogen chloride, and hydrogen fluoride) and other hazardous chemical fumes from industrial exhaust streams. These systems are crucial in mitigating air pollution and protecting the environment and human health, especially in industries where corrosive or toxic gases are produced.

Design Architect

Functionalities continually to prospective intellec

Modern Equipment

Functionalities continually to prospective intellec

24/7 Hrs Supports

Functionalities continually to prospective intellec

Finished Timely

Functionalities continually to prospective intellec

Here's how an acid fume scrubber typically works

-

Inlet

The polluted air, laden with acidic fumes, is drawn into the scrubber from an industrial process through an inlet duct.

-

Contact with Scrubbing Solution

Inside the scrubber, the polluted air comes into contact with a liquid scrubbing solution. This solution is often water-based and may contain various chemicals or additives depending on the specific pollutants to be removed. The scrubbing solution can neutralize or chemically react with the acidic gases.

-

Absorption and Reaction

As the acidic fumes come into contact with the scrubbing solution, chemical reactions occur, leading to the removal of the acid gases from the air. For example, in the case of sulfur dioxide (SO2) removal, the reaction might produce sulfuric acid (H2SO4), which is then dissolved in the liquid solution.

-

Separation

The cleaned air, now largely free of acid gases and other pollutants, exits the scrubber through an outlet duct and is released into the atmosphere or further treated if necessary.

-

Treatment of Scrubbing Solution

The liquid scrubbing solution, now containing absorbed pollutants, needs to be treated or regenerated for continuous use. Depending on the specific system, this can involve chemical reactions, pH adjustment, or additional treatment steps to recover or neutralize the absorbed pollutants.

Acid fume scrubbers are commonly used in various industries, including chemical manufacturing, metal smelting, power generation (especially in coal-fired power plants), and semiconductor manufacturing, among others. The choice of scrubbing solution and scrubber design depends on the specific contaminants to be removed and the efficiency required.

There are various types of scrubbers, including packed bed scrubbers, spray tower scrubbers, and venturi scrubbers, each with its own advantages and applications. The selection of the appropriate type of scrubber depends on factors such as gas flow rate, pollutant concentration, and space constraints.

In summary, acid fume scrubbers play a crucial role in reducing air pollution by removing acidic gases and other harmful chemical fumes from industrial processes, making the emissions more environmentally friendly and safer for human health.

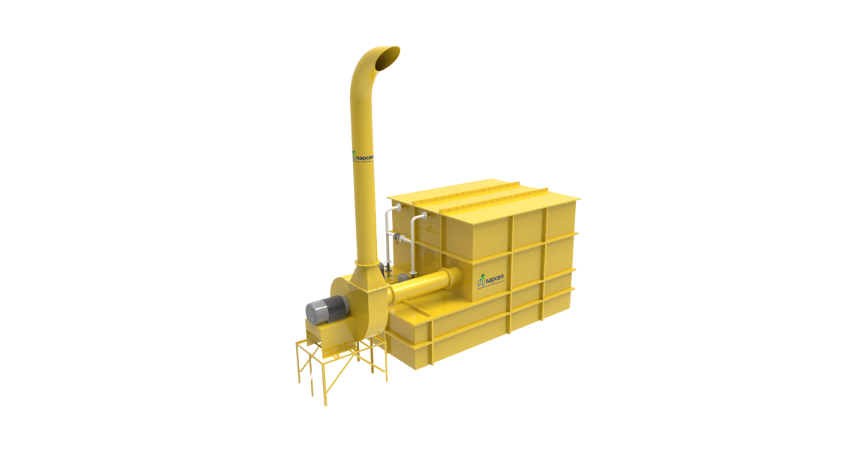

Mist Collectors

An Ammonia Scrubber is a specialized air pollution control device used to remove ammonia (NH3) gas from industrial processes, air emissions, or wastewater. Ammonia is a common pollutant in various industries, and scrubbers are employed to prevent its release into the atmosphere or water bodies, as high ammonia concentrations can have detrimental effects on the environment and human health.

Design Architect

Functionalities continually to prospective intellec

Modern Equipment

Functionalities continually to prospective intellec

24/7 Hrs Supports

Functionalities continually to prospective intellec

Finished Timely

Functionalities continually to prospective intellec

Here's how an ammonia scrubber typically works

-

Inlet

Ammonia-laden air or gas enters the ammonia scrubber from an industrial process or emission source.

-

Scrubbing Solution

Inside the scrubber, there is a liquid solution, often water-based, which may contain chemicals or reagents designed to react with and capture ammonia. The choice of scrubbing solution depends on the specific application and the concentration of ammonia to be removed.

-

Gas-Liquid Contact

The incoming gas is brought into contact with the scrubbing solution. Ammonia gas molecules dissolve into the liquid phase due to chemical reactions between the ammonia and the scrubbing solution. These reactions may involve acid-base reactions or other chemical processes, depending on the specific scrubber design.

-

Separation

After the ammonia gas has been absorbed by the scrubbing solution, the clean air exits the scrubber, while the ammonia-rich liquid is collected at the bottom of the scrubber vessel.

-

Recovery or Treatment

In some cases, the collected ammonia-rich liquid can be treated or further processed to recover ammonia for reuse or safely dispose of it, depending on the specific application.

Ammonia scrubbers are commonly used in various applications, including

-

Agriculture

To control ammonia emissions from animal husbandry operations, such as poultry and swine farms.

-

Chemical Manufacturing

To capture and control ammonia emissions from chemical production processes.

-

Wastewater Treatment

To remove ammonia from wastewater streams to meet regulatory discharge limits.

-

Industrial Facilities

To control ammonia emissions from various industrial processes, such as refrigeration, petrochemical, and food processing.

-

Air Pollution Control

To reduce ammonia emissions from industrial stacks and exhausts to comply with air quality regulations.

The design and operation of ammonia scrubbers can vary depending on the specific application and the concentration of ammonia in the gas stream. Engineers and environmental experts assess the requirements and select the appropriate type of scrubber and absorbent solution to effectively remove ammonia while considering factors like cost, efficiency, and environmental regulations.

Proper maintenance and monitoring of ammonia scrubbers are crucial to ensure their continued effectiveness in reducing ammonia emissions and environmental impact.

Pumps

A Chlorine Scrubber, also known as a chlorine gas scrubber or chlorine gas absorber, is a device or system designed to remove chlorine gas from industrial or environmental air emissions. Chlorine gas is toxic, corrosive, and can pose significant health and environmental risks if released into the atmosphere. Therefore, it is essential to control and mitigate chlorine gas emissions, especially in industries where chlorine is used or produced.

Design Architect

Functionalities continually to prospective intellec

Modern Equipment

Functionalities continually to prospective intellec

24/7 Hrs Supports

Functionalities continually to prospective intellec

Finished Timely

Functionalities continually to prospective intellec

Here's how a chlorine scrubber typically works

-

Gas Inlet

The chlorine gas-laden air is directed into the scrubber from the emission source, such as a chemical plant or water treatment facility.

-

Scrubbing Media

Inside the scrubber, there is a chemical scrubbing media or solution. Commonly used scrubbing solutions include sodium hydroxide (caustic soda) or sodium bisulfite. These chemicals react with chlorine gas to form less harmful compounds like sodium hypochlorite (bleach) or sodium chloride (table salt).

-

Contact between Gas and Scrubbing Solution

The chlorine gas-laden air comes into contact with the scrubbing solution, and a chemical reaction occurs, converting the chlorine gas into a less hazardous form.

-

Neutralization

The chlorine gas is neutralized by the scrubbing solution, effectively removing it from the air.

-

Outlet

The cleaned air is released into the atmosphere, free from chlorine gas.

Chlorine scrubbers are commonly used in various industrial applications, including chemical manufacturing, water treatment plants, and wastewater treatment facilities, where chlorine is used for disinfection purposes. Scrubbers help ensure compliance with environmental regulations by preventing the release of chlorine gas into the air.

The choice of scrubbing solution and the design of the scrubber system may vary depending on the specific application and the concentration of chlorine gas in the emissions. Additionally, monitoring systems are often integrated into chlorine scrubbers to ensure the effectiveness of gas removal and to provide alarms or shutdown mechanisms in case of system malfunctions.

It's crucial to operate and maintain chlorine scrubbers properly to ensure their effectiveness in safeguarding both the environment and human health. Regular maintenance and monitoring are essential to prevent accidental releases of chlorine gas and maintain a safe working environment.

Blower

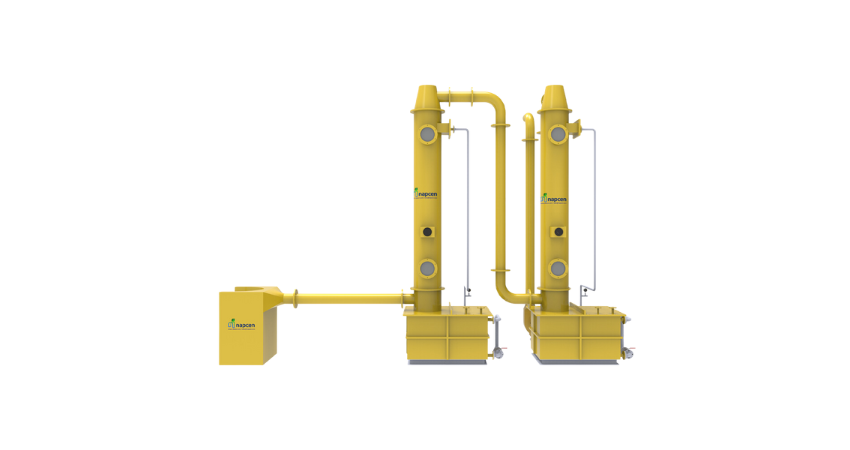

A Packed Bed Scrubber is a type of air pollution control device used to remove pollutants, primarily particulate matter and gases, from industrial exhaust gases or process streams. It is commonly employed in various industries, including chemical processing, petrochemical, pharmaceuticals, and wastewater treatment

Design Architect

Functionalities continually to prospective intellec

Modern Equipment

Functionalities continually to prospective intellec

24/7 Hrs Supports

Functionalities continually to prospective intellec

Finished Timely

Functionalities continually to prospective intellec

Here are the key components and working principles of a Packed Bed Scrubber

-

Packing Material

The heart of a packed bed scrubber is the packing material. It is typically a bed of various materials, such as plastic or metal structured packing, random packing, or special materials designed to maximize the contact between the contaminated gas stream and a scrubbing solution.

-

Scrubbing Solution

The contaminated gas stream is brought into contact with a scrubbing solution. This solution can be water or other chemical solutions depending on the pollutants being removed. For example, in the case of acid gas removal, an alkaline solution like sodium hydroxide (caustic) or calcium carbonate (lime) may be used.

-

Gas Inlet

Polluted gas enters the scrubber through an inlet and flows upward through the packed bed.

-

Counter flow or Cross flow

There are typically two configurations for packed bed scrubbers: counter flow and cross flow. In counter flow, the gas flows upward while the scrubbing solution flows downward. In cross flow, both the gas and scrubbing solution flow horizontally. Counter flow arrangements are more efficient in terms of gas-liquid contact but may require more energy to operate.

-

Mass Transfer

As the gas rises through the packing material, it comes into intimate contact with the scrubbing solution. Pollutants in the gas are transferred into the liquid phase through absorption or chemical reaction, depending on the nature of the pollutants and the scrubbing solution used.

-

Mist Elimination

After passing through the packing material, the gas may still carry small droplets of scrubbing solution. Mist eliminators, such as demisters or chevron-type separators, are used to remove these droplets before the gas exits the scrubber.

-

Outlet

Cleaned gas exits the scrubber through an outlet.

-

Overflow and Re-circulation

Excess scrubbing solution that collects at the bottom of the scrubber is usually drained and re-circulated back to the top of the packed bed to ensure efficient use of the scrubbing liquid.

Packed bed scrubbers are effective at removing a wide range of pollutants, including particulate matter, acid gases (such as sulfur dioxide and hydrogen chloride), and volatile organic compounds. The choice of scrubbing solution and packing material depends on the specific application and the pollutants to be removed.

One advantage of packed bed scrubbers is their high removal efficiency, but they can be energy-intensive due to the pressure drop caused by the packing material. Additionally, maintenance is required to prevent packing material fouling and ensure proper operation.

Spray Nozzle

A Hard chrome scrubber typically refers to a piece of equipment or a system used in industrial processes, especially in air pollution control or wastewater treatment. The term "hard chrome" refers to a type of chrome plating that is highly corrosion-resistant and durable, making it suitable for harsh industrial environments.

A hard chrome scrubber is likely used in the context of removing or scrubbing harmful pollutants or contaminants from exhaust gases or liquid effluents.

Design Architect

Functionalities continually to prospective intellec

Modern Equipment

Functionalities continually to prospective intellec

24/7 Hrs Supports

Functionalities continually to prospective intellec

Finished Timely

Functionalities continually to prospective intellec

Here's how it generally works

-

Pollutant Capture

The industrial process generates emissions or waste streams that contain harmful substances, such as particulate matter, volatile organic compounds (VOCs), acid gases, or heavy metals.

-

Scrubbing System

The hard chrome scrubber is part of a scrubbing system that captures these pollutants before they are released into the environment. The scrubber typically consists of a chamber or vessel equipped with various components and media designed to capture the specific pollutants of concern.

-

Scrubbing Media

The scrubber may use various media or substances to capture pollutants. These could include materials such as activated carbon, chemical reagents, or other specialized materials that can adsorb, react with, or otherwise remove the pollutants from the gas or liquid stream.

-

Gas-Liquid Contact

In the case of gas emissions, the contaminated gas is passed through the scrubbing chamber, where it comes into contact with the scrubbing media. In the case of liquid waste, the contaminated liquid is circulated through the scrubber.

-

Chemical Reactions

Depending on the pollutants involved, chemical reactions may occur within the scrubber. For example, in the case of acid gas removal, alkaline reagents like sodium hydroxide or calcium carbonate might be used to neutralize the acids.

-

Pollutant Removal

The pollutants are removed or transformed within the scrubber, leaving behind cleaner exhaust gases or treated effluents.

-

Disposal or Recovery

The captured pollutants can be disposed of safely or, in some cases, recovered for reuse or recycling, depending on their nature.

Hard chrome scrubbers are often used in industries such as metal finishing, semiconductor manufacturing, chemical processing, and power generation, where strict environmental regulations require the removal of hazardous or harmful substances from exhaust gases or wastewater.

It's important to note that the design and operation of a hard chrome scrubber can vary significantly depending on the specific pollutants to be removed and the industrial process involved. Different scrubber technologies, such as wet scrubbers, dry scrubbers, or electrostatic precipitators, may be used based on the requirements of the application.